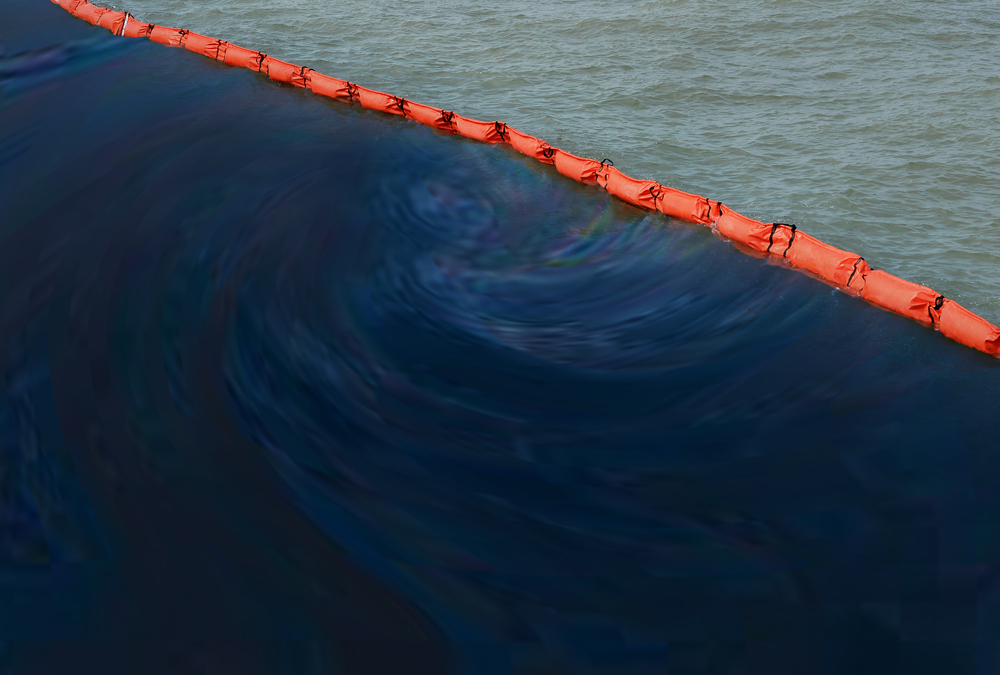

Containment Boom in Oil Spill Response

An oil spill can pose significant environmental threats and can be challenging to contain and clean up. Sensitive locations such as shorelines that are threatened by advancing oil slick can be protected using various equipment. Booms are floating, physical barrier to oil, made from plastic, metal or other materials, which contain and slow the spread of oil.

Booms come in a variety of shapes and sizes, many of which are suited for specific types of water conditions and environments. They are usually deployed using mooring systems, such as anchors and land lines. Depending on the situation, a boom may be placed:

- Around a sensitive site to prevent oil from reaching it

- Across an entrance to the ocean, for example a small inlet, stream outlet or marina, to close off that entrance so oil cannot pass through into sensitive habitats

- Somewhere the boom can deflect oil away from sensitive locations such as beaches or shellfish beds

Booms also help make recovery easier by concentrating the oil in thicker surface areas so skimmers (collection boats) or other devices can remove oil from the sea surface more effectively.

Boom Types and Methods

There are three types of booms. A hard boom is the most common and is similar to a floating piece of plastic with a cylindrical float and the top that is weighted at the bottom. Sorbent booms look like long sausages made out of a material that can absorb oil. However, these cannot contain oil for long. Fire booms look like metal plates with a floating cylinder at the top and thin metal plates in the water. These are made to contain oil long enough to be lit on fire and burned up. This response to oil spills is controversial however and rarely used.

Common booming tactics (using a hard boom) includes:

- Diversion booming – Where a boom is specifically placed to divert oil to a collection point.

- Deflection booming – Placing a boom in order to deflect contamination away without collecting it. This generally isn’t used for oil spills.

- Exclusion booming – A boom is placed around the entire spill to block it off from a sensitive area. Can be ineffective in fast currents or tides.

- Containment booming – The boom is placed to hold or slow the movement of contamination.

Alternative measures responders may consider (if local authorities agree) includes in situ burning and chemical dispersants. The former involves igniting the oil before it reaches the coast and was famously used during the 2010 BP oil spill in the Gulf of Mexico.

The latter uses chemicals to disperse the oil into the water so it doesn’t stay on the surface where it could affect beaches and other sensitive areas. Obviously these methods are not the most environmentally friendly and should be avoided where possible.

OLEOLOGY Rapid Deployment Boom

Modern technology used to respond to oil spills is drastically improving, with faster, more efficient skimmers and rapid deployment booms, both of which allow a more effective and timely response. This is especially helpful for marinas and yacht clubs, where a single person can quickly deploy a boom system when a spill occurs thanks to the lightweight and easy to deploy system.

50 metres of the MyCelx rapid development boom weighs less than 15kg and can be deployed in less than a minute, preventing damage to the marina and the environment. Watch this video to see how this new technology works.

OLEOLOGY delivers high quality oil spill equipment which is scalable and custom-designed to suit the needs of each client. We help organisations around Australia and New Zealand find cost-effective solutions to prevent environmental damage and reduce liability. For more information, call us today on 1300 305 723 or contact us online.