Where Conventional Systems Fail

Conventional systems attempt to remove oil and hydrocarbons from water using mechanical

separation or chemical injection, often involving long, complex processes that are prone

to

bottlenecks and failures. These systems can even re-release oil back into the water when

the

composition or load changes. In contrast, MyCelx doesn’t simply filter or separate oil —

it

permanently binds with it at the molecular level, ensuring oil is never released back

into

the water. This results in lower ppm levels and finer droplet removal than any other

system

currently available.

MyCelx offers a scientific and reliable solution for removing oil and hydrocarbons from

produced water, process water, or wastewater for recycling and reuse. It meets and

exceeds

stringent water purity regulations that conventional methods often fail to achieve.

MyCelx

enables rapid, cost-effective compliance with environmental standards, providing a

dependable option when other systems fall short.

Environmentally friendly and operationally efficient, MyCelx keeps oil confined within

the

production environment, reducing ecological risks. It can be used as a complete

replacement

for conventional systems or as a supplemental, emergency solution where mechanical

oil-water

separators underperform. Adopting MyCelx can drive innovation and significant

operational

improvements, delivering more efficient and lower-cost oily water treatment.

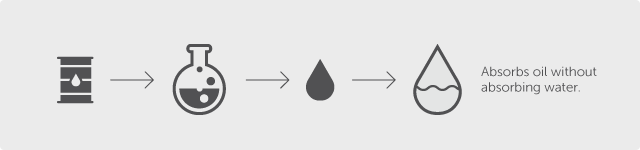

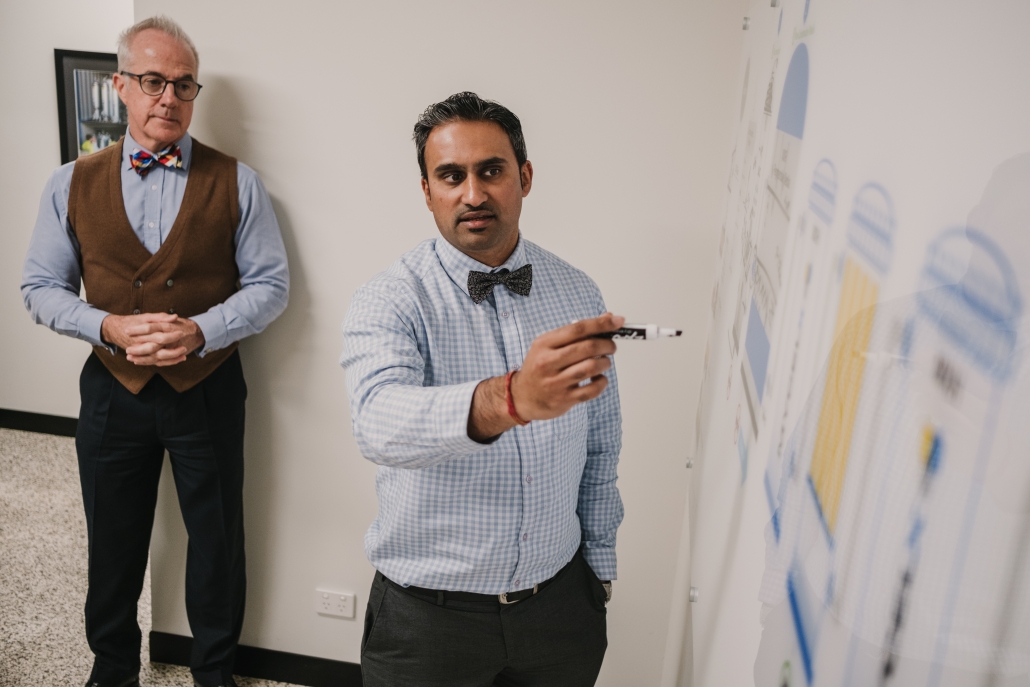

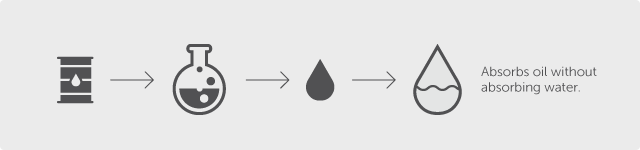

MyCelx is an advanced oil-free water technology designed for the oil and gas, mining, and

water treatment industries. Unlike conventional filters or chemical treatments, MyCelx

uses molecular cohesion to permanently remove oil from water, achieving critically low

levels of less than 1 ppm—far below standard regulatory requirements. Recognised by

government and environmental authorities, the treated water is safe for recycling or

discharge, such as for use in dust suppression.

What does your Environmental Regulator require for compliant

discharge?

Each state in Australia has specific discharge limits and waste

disposal regulations, and OLEOLOGY brings deep expertise in navigating these

requirements to help submit successful applications. With extensive field

experience, our team has presented numerous webinars to the EPA and DWER, sharing

insights on the latest advancements in water treatment technologies. Every OLEOLOGY

system is engineered for high performance in real-world conditions, backed by

unmatched industry knowledge. To learn more about our treatment process and how it

compares to other technologies, watch the video above.