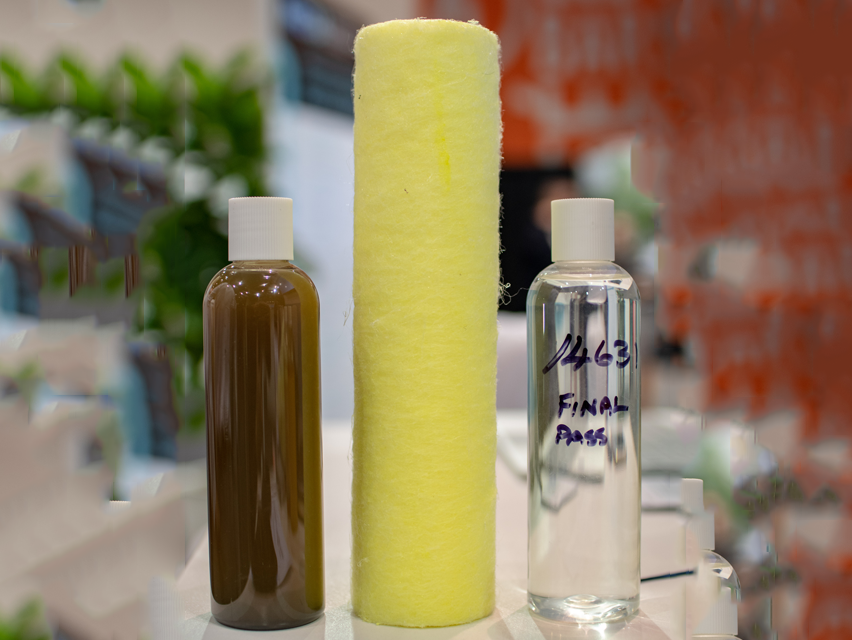

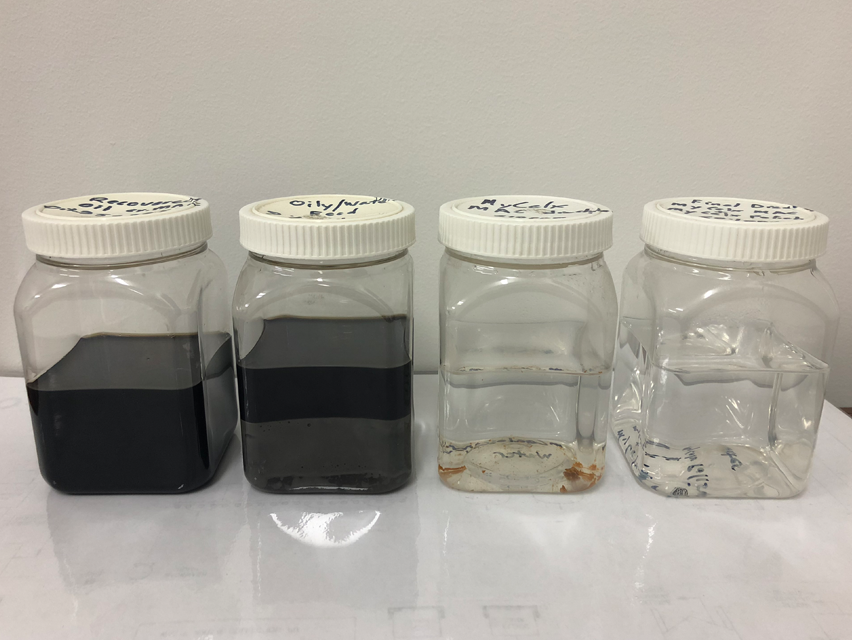

MyCelx doesn’t just mechanically filter or separate oil – it permanently binds with oil through molecular cohesion. Once oil comes in contact with MyCelx, it cannot be released back into the water. MyCelx provides the lowest ppm levels and smaller droplet size removal than any other system on the market.

Scientific, Reliable Oil & Hydrocarbon Removal

MyCelx systems use a scientific and reliable approach for removing oil and hydrocarbons for produced and process water or wastewater recycling and reuse. MyCelx answers the call for meeting and exceeding regulations for water purity. When you are unable to meet strict enforcement levels with conventional approaches, MyCelx can help you meet or exceed those standards quickly, efficiently and at a surprisingly low cost.

MyCelx is an ecologically friendly water treatment – protecting the environment and your operation by keeping oil where it should be: inside your production environment.

MyCelx can be deployed as emergency and remedial measures to supplement conventional oil water separators. These systems rely on mechanical separation by SG differential and do not meet required goals, however, MyCelx can be used as a complete replacement of conventional systems. The MyCelx change can be a decisive and innovative driver of operational improvement for more efficient and lower cost oily water treatment.