Gold Mine Wash Bay Recycling

CUSTOMER: International Gold Mining Producers

LOCATION: Rural Western Australia

Application Overview

Water Recycling from Heavy & Light Vehicle Washbay

FLOW RATE

Up Lo 30cu.m/hr (720 KL/day)

OBJECTIVE

Treat water from Heavy and Light Vehicle Wash bays

Save Water – Recycle Water at HV/LV Wash Bay

Increase Water Supply for other Facilities

Recycled Water Quality to Department of Health and Mine License for Discharge

PROCESS WATER (INLET):

| Free Oil in Water | 100+ ppm (mg/L) |

| Suspended Solids | 400-500ppm |

| Heavy Oil & Fuel Emulsions | Up to 50ppm |

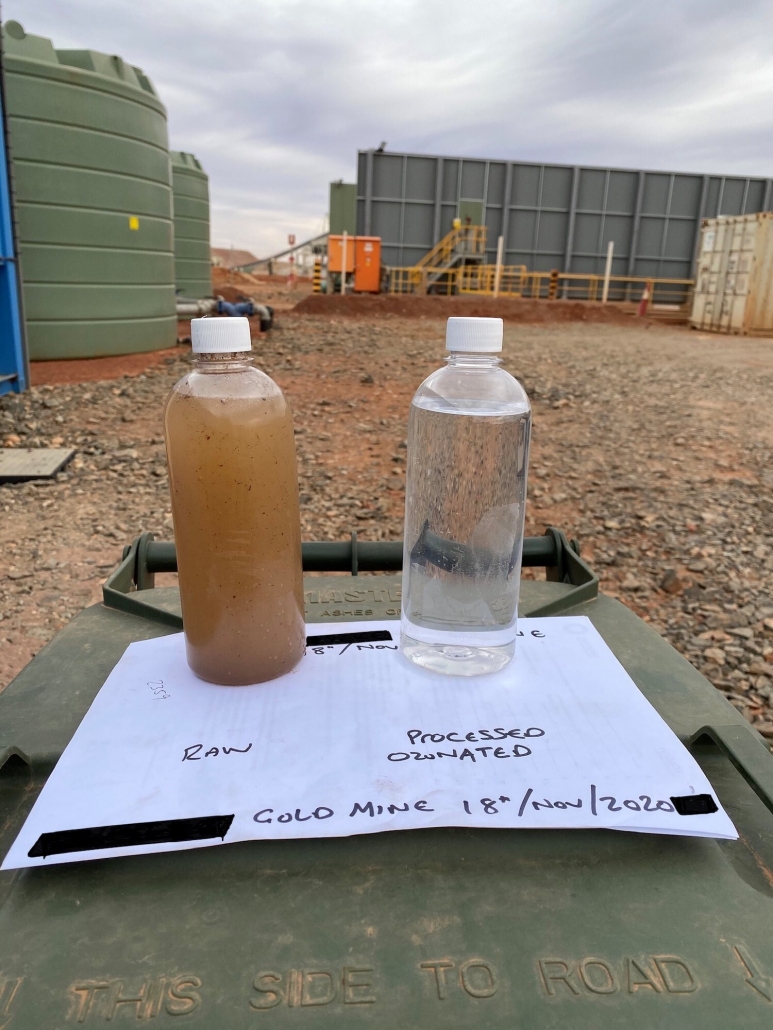

RESULTS – DISCHARGE AFTER OLEOLOGY TREATMENT SYSTEM:

| Oil in Water | 0-2 ppm (mg/L) |

| Suspended Solids | <5 ppm |

| Legionella and E. Coli. | <1 CFU/100mL |

| Sheen free and Odour free |

FOOTPRINT:

40ft Containerised Treatment System (12m x 2.5m)

Company profile

Joint venture between two major gold mine producers

Management of Production and Non-Production Facilities

Business Situation

An existing mine site with limited water supply required a multi facet answer to increase water supply from the RO, decrease maintenance costs, and improve water quality from the wash bay treatment system.

Limited budget for the critical water treatment to meet Department of Health requirements. Site installation is required to be minimal to achieve a low-cost solution (CAPEX and OPEX).

Technical situation

The average daily amount (650KL) of water contained:

- Surfactants / detergents (emulsifiers)

- Hydrocarbon spikes from refuel spills/bund areas (from previous sites analysed at 3% or 30,000ppm)

- Hydraulic oils & engine oils contain emulsifying agents as a part of the oil’s chemistry

Treated water is directed to a pond and must be compliant with environmental regulations, mine license and meet Department of Health requirements for recycling.

Solution

The existing RO did not require an upgrade, as supply was redirected to other processing facilities and the wash bay was able to recycle treated from the OLEOLOGY Wash Water Treatment System (WWTS).

The compact OLEOLOGY WWTS is a staged filtration process to further remove; free & dispersed oils via the MyCelx Advanced Coalescer (MAC) (stage 1), oily solids & emulsions through two MXR’s (stage 2) followed by MyCelx cartridge filters removing dispersed & stable emulsions along with soluble hydrocarbons (stage 3). Final stage (4) by Advanced Oxidation Process (AOP) treatment to further polish and maintain water quality in the hot climate and ensure sanitation in line with Dept of Health guidelines.

Water treated to 2ppm (parts per million), suitable for reuse as wash water and/or dust suppressant onsite. The automatic backwashing of the filtering media is PLC controlled, maintaining efficacy and service life of the system and importantly monitoring the discharge water quality.

Benefits & Impact

- Reduced water usage, treated water may be reused for washing and dust suppression

- Minimal installation and commissioning time/cost due to containerised (40ft), plant tested and ready for site installation

- Minimal running costs, no chemicals required

- Risk reduction for environmental compliance (mine license)

- Reduced maintenance costs due to minimal staff intervention and minimal filter changes

Further Information

Please call OLEOLOGY 1300 948 756 (option 1) or email tech@oleology.com.au