Case Study – Gold Mine Wash Water Treatment & Recycling

Client

Well known gold miner and producer north east of Kalgoorlie, building a new mine to be managed by a major EPCM.

Project overview

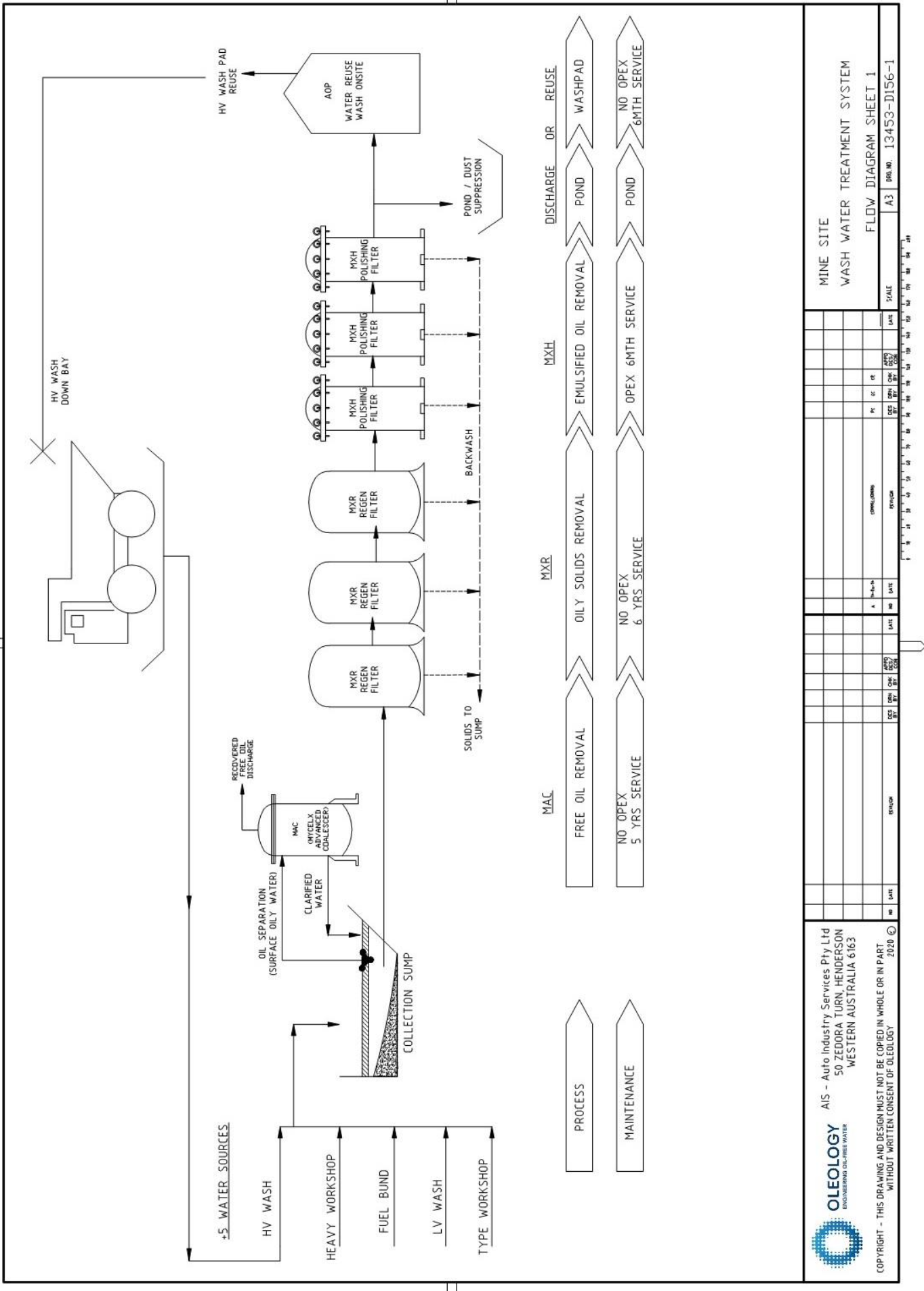

A new gold mine project northeast of Kalgoorlie required a water treatment solution to treat waste water from heavy and light vehicle wash bays, tyre bay, refuel bay and wastewater from heavy and light vehicle workshops, all directed to the HV wash bay sump

Challenge

The mine design as proposed, the client observed a heavy draw of water from the Reverse Osmosis (RO) produced water for non-process infrastructure use, mostly the HV wash bays at site, and that additional CAPEX for a second RO would possibly be required as the mine capacity grew, the start of the project build.

Scope

OLEOLOGY was approached to value engineer the proposed layout for potential savings in site water usage, as well as challenged for savings, both CAPEX and OPEX with the current proposed water treatment design.

Water treatment rate – 500Kl per day Environmental discharge quality – <5ppm (parts per million) hydrocarbon.

Water Quality

As a new project water quality for this mine was not available.

OLEOLOGY utilized water data / sampling from similar mines as a basis for scrutiny of the current treatment design that was presented.

Mine Site Water quality typically shows

| Oil in Water 50 – 3,000 ppm (mg/L) | Hydraulic Oil |

|---|---|

| Total Suspended Solid (TSS) >300ppm (mg/L) | Glycol (coolant) |

| Heavy Oil | MBAS (Detergents) |

| Fuel Emulsions |

Hydrocarbon spikes from refuel spills/bund areas from previous sites were analyzed at 3% or 30,000ppm.

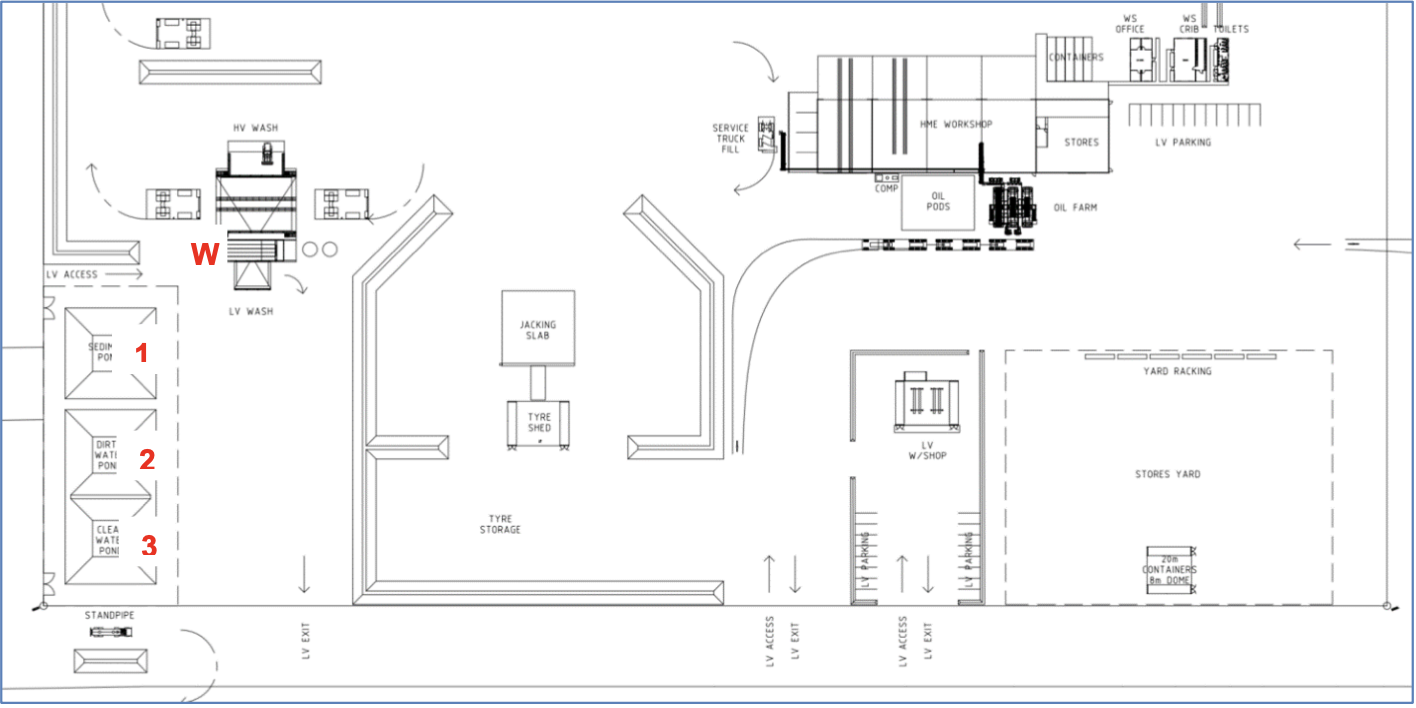

Original Client Design

Overview of water flow in original design

Wash Water

Supplied to the wash bay by two 34,000Lt above ground poly tanks (shown to the right of the wash bay sump with a number) fed by the mine RO.

Wastewater (all sources)

Would be collected in the wash bay drive-in sump (W) with built in weir, pumped to a sediment pond (1), water would overflow through a pipe to a dirty water pond (2). Water in the dirty water pond would be treated for hydrocarbon and other contaminants by an advanced gravity separation technology (Ultraspin) then discharged to the Treated water pond (3) for use as dust suppressant.

Challenges observed by OLEOLOGY with original design

- Extra RO water would be required as mine production lifted & vehicles increased

- Required water quality at discharge was not going to be viable with conventional systems

- Wash water being fed from the wash bay pad to the sump was entering at the lower end of the ramp not allowing for full settling time of larger solid to occur.

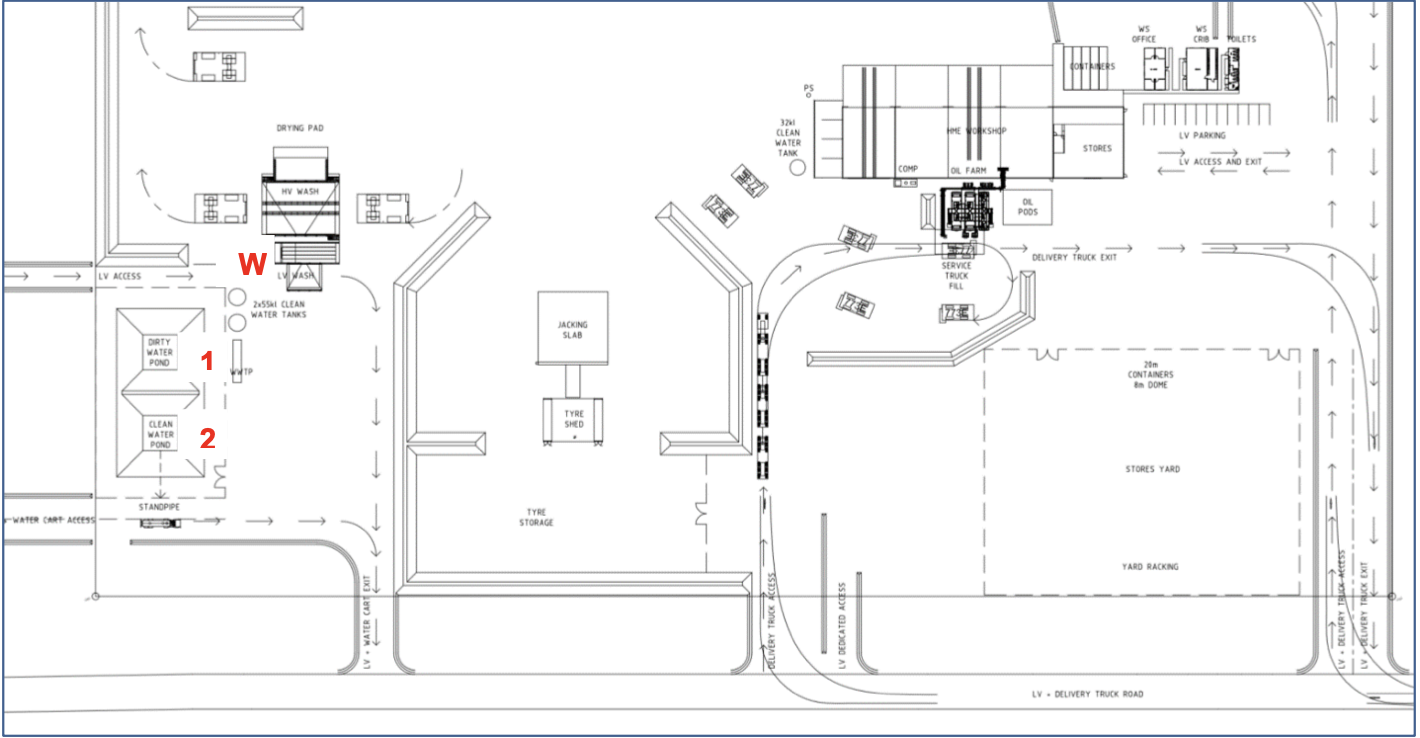

OLEOLOGY Revised design

Overview of water flow in OLEOLOGY design

Wash Water

Supplied to the wash bay by two 50,000Lt above ground poly tanks (shown to the right of the ponds) fed by recycled water from the OLEOLOGY water treatment solution.

Wastewater (all sources)

Would be collected in the wash bay drive-in sump (W) with built in weir, pumped to a dirty water pond (1). Water is treated for hydrocarbon and other contamination by a staged sequence of MyCelx in an OLEOLOGY containerized treatment plant and discharged to 2 x 50,000 L

above ground poly tanks for re-use on the wash bay.

A standalone pond (2) fed by bore water is used for dust suppression.

Benefits achieved by implementing OLEOLOGY design

- Reduced RO water demand by NON process infrastructure at site

- Water Quality – reuse & discharge – achieved Dept of Health & DWER.

- CAPEX Removal of a proposed pond in the first design saving.

- OPEX Reduced – no chemical dosing for water treatment.

- OPEX Reduced minimizing waste – oil & dry waste

- HSE improved – No chemical handling No Chemical storage for water treating

- PLC Remote operation, monitoring & diagnostics lowered OPEX – resources, scheduling & maintenance reductions.

- Reduced install and commissioning process – complete containerized plant equipment.

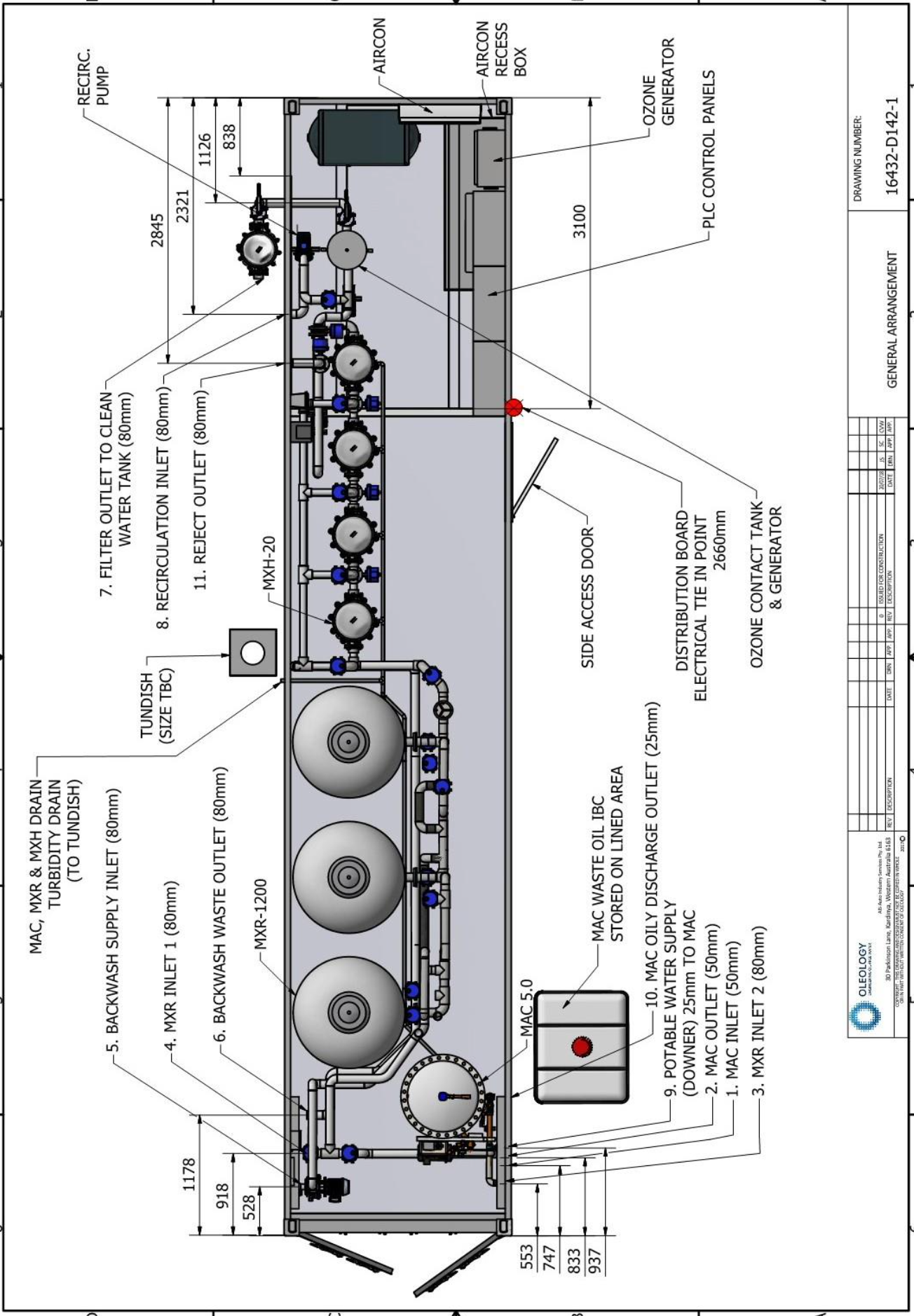

Conclusion Summary – OLEOLOGY WTP

- Re-designed, project managed delivery of water / energy /cost saving plant

- Water Treatment Plant delivered on time

- Delivered safely – NO incidents

a.Minimum site work – complete plant shipped as one unit 40ft container - Delivered on budget – NO Variations

- Water Treatment Quality exceeds specification

a. Recycle wash water – exceeds Dep’t of Health requirements

b. Flow rate exceeds the requirement

c. CAPEX greatly reduced

i. Reduced civil works required – smaller footprint for container plant

ii. Reduced civil works

1. 1 x Pond removed

2. Pond associated pipe work removed

iii. Site Installation reduced – complete plant shipped to site

iv. Site commissioning reduced

d. OPEX reduced

i. Smart / monitoring technology – Maintenance on schedule

ii. Waste removal reduced – dry filters at 6 month only

iii. Site utility resources reduced monitoring & maintenance

iv. No chemicals required

v. No chemicals – Improved Safety – No HSE implications handling/storage - Delivered an operating system to INNOVATION design