Bilge Water Treatment

On board treatment or onshore treatment available – contact us to find out what is suitable for your needs.

Case Study 1

Workboat fleet installs MyCelx Bilge Systems to allow overboard bilge water discharge.

Background

Many workboats do not have bilge water systems that allow legal overboard discharge of their bilge water. Bilge water must be pumped out at dockside and taken for treatment at costs ranging as high as $1.50 per litre.

The Problem

An east coast marine salvage and dredging company wanted to reduce their very high annual bilge water treatment costs by installing on-board treatment systems. Traditional on-board separator systems required a high capital investment and if emulsified oils are present, do not meet discharge standards.

The Solution

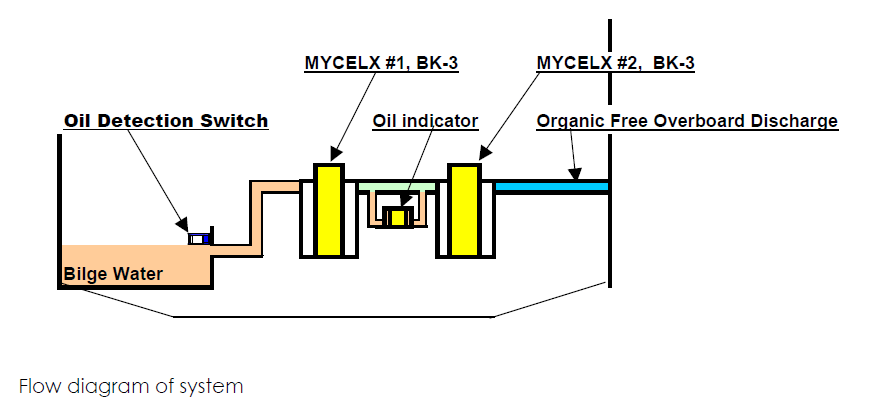

MyCelx supplied a filtration system for the first workboat consisting of a sump pump, an “oil smart” switch, oil indicator, and two bilge filters. The bilge water is pumped from the bottom of the bilge through the two filters in series and discharged. The oil smart switch permits the water layer (only) to be pumped to the filters. The oil layer remains in the bilge until it can be pumped to the slop tank or ashore. The oil indicator visually denotes when the filters are due to be changed.

The Results

This system has been operating for 6 months with all bilge water being successfully discharged overboard. Replacement filter costs have amounted to less than two cents per gallon. The same system is now being installed on the remainder of the workboat fleet at a cost of $900 per vessel.

The Benefits

By being able to discharge over 90% of the contents of the bilge over the side, this company is saving $0.48 per gallon on their bilge water treatment costs.